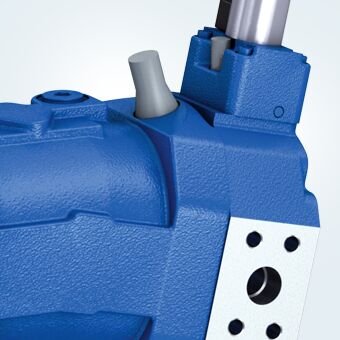

Axial piston motors

Axial piston motors are a type of hydraulic motor that uses a piston that moves axially (parallel to the axis of rotation) to generate rotational motion. These hydraulic motors are used in a variety of applications, including:

- Heavy industry: Axial piston hydraulic motors are used in heavy equipment such as excavators, loaders, and cranes.

- Mining: Axial piston hydraulic motors are used in mining equipment such as dump trucks and loaders.

- Construction: Axial piston hydraulic motors are used in construction equipment such as concrete mixers and concrete pumps.

The advantages of axial piston hydraulic motors are:

- High efficiency: Axial piston hydraulic motors have high efficiency in converting hydraulic energy into mechanical energy.

- Stable performance: Axial piston hydraulic motors can operate stably under a variety of operating conditions

- Long durability: Axial piston hydraulic motors are designed for long durability and can operate under severe operating conditions.

Here are some commonly used codes for Axial Piston Motors:

- A2FE: Axial piston hydraulic motor with a compact design and high efficiency.

- A6VM: Axial piston hydraulic motor with a wide displacement range and stable performance.

- A10VM: Axial piston hydraulic motor with a simple and reliable design, suitable for mobile applications.

- A11VO: Axial piston hydraulic motor with a large displacement and optimal performance for heavy-duty applications.

These codes are typically used by manufacturers such as Bosch Rexroth and can vary depending on the manufacturer and the type of hydraulic motor used. Some codes may also have additional variations indicating specific features or configurations, such as displacement size, control type, or other options.

Axial Piston Motors can be used in various industry segments, including:

- Construction Industry: Used in equipment such as excavators, loaders, and cranes to drive components that require hydraulic power.

- Mining: Used in mining equipment such as dump trucks, loaders, and excavators to drive components that require hydraulic power.

- Agricultural Industry: Used in agricultural equipment such as tractors and harvesters to drive components that require hydraulic power.

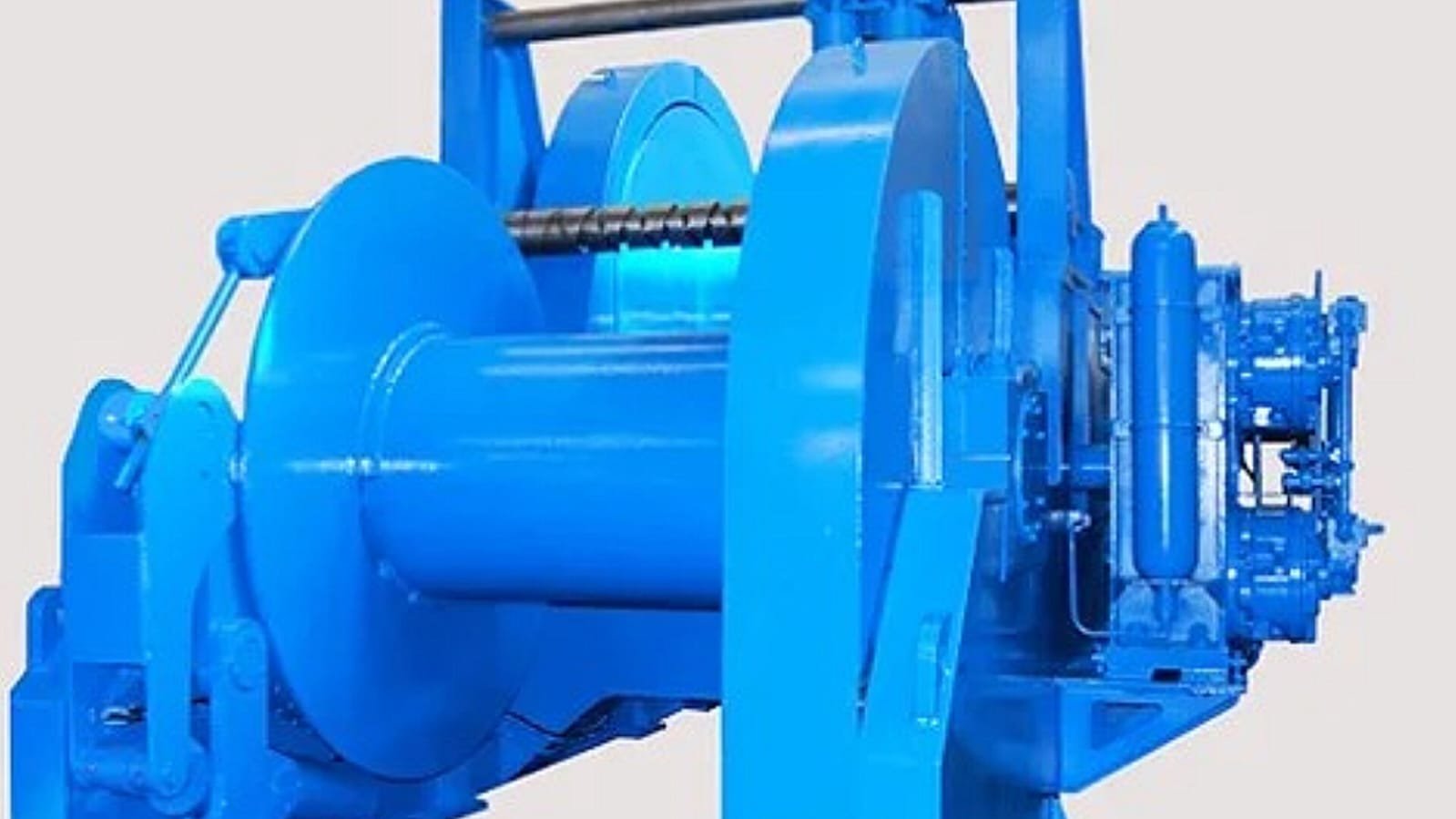

- Maritime Industry: Used in ship equipment such as winches and cranes to drive components that require hydraulic power.

- Manufacturing Industry: Used in production equipment such as presses and cutting machines to drive components that require hydraulic power.

Axial Piston Motors can also be used in various other applications, such as:

- ydraulic systems: Used as a drive in a hydraulic system to drive components that require hydraulic power.

- Drive systems: Used as a drive in a drive system to drive components that require hydraulic power.

Thus, Axial Piston Motors can be used in a wide range of industries and applications that require efficient and reliable hydraulic power.

” We are the official distributor of Rexroth and have spent several decades building trust and offering quality products to be an industry leader in the manufacturing and supply of hydraulic systems, lubrication systems, filtration systems, and fire suppression systems. “