Hydraulic cylinders are hydraulic components used to produce linear motion or move loads in hydraulic systems. They work by using hydraulic fluid pressure to move a piston within a cylinder, thus producing linear motion.

Hydraulic cylinders have several applications, including:

- Construction industry

Used in equipment such as excavators, loaders, and cranes to move arms, buckets, and other components.

- Mining industry

Used in mining equipment such as dump trucks and loaders to move bodies and other components.

- Manufacturing industry

Used in production equipment such as presses and cutting machines to move components that require linear motion.Hydraulic cylinders have several advantages, including:

Baca Juga : Axial Piston Pump

High power: Can produce high power to move heavy loads.

- Stable motion

Can produce stable and controlled motion

- Reliable

Can operate reliably under harsh working conditions.

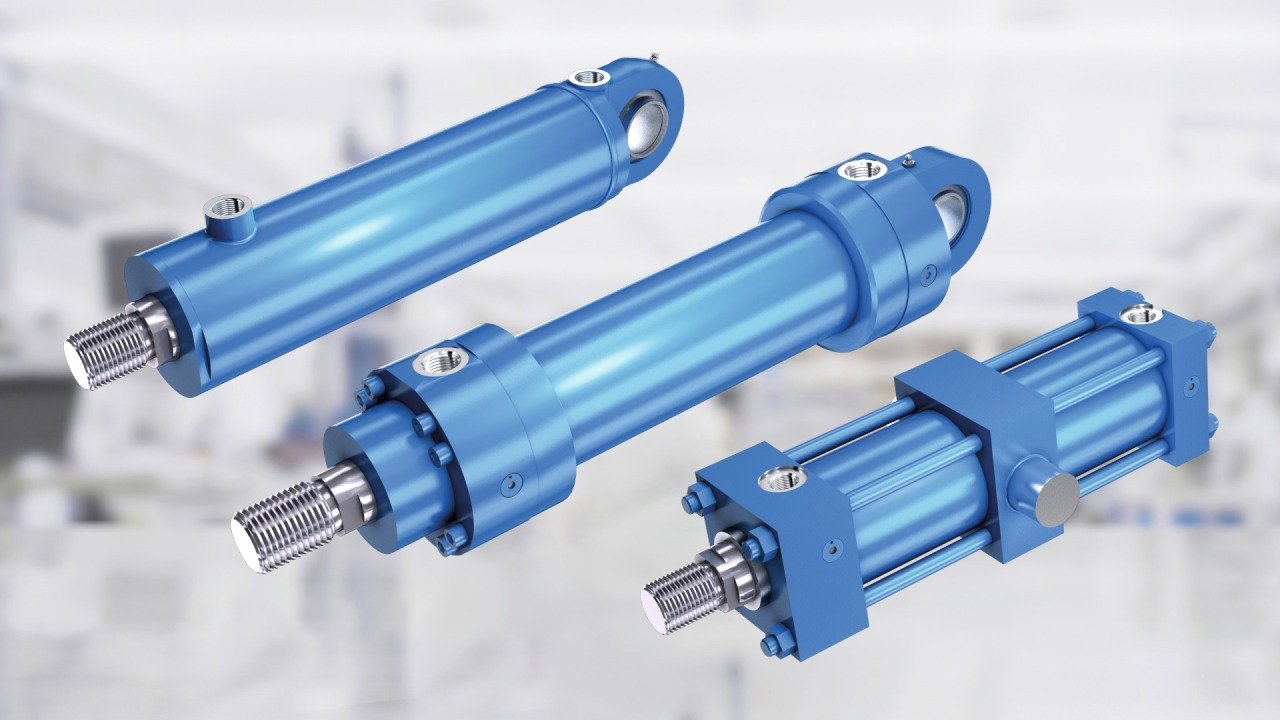

Commonly used types of hydraulic cylinders are:

- Single-acting cylinder

Has only one hydraulic port and can move a load in one direction.

- Double-acting cylinder

Has two hydraulic ports and can move a load in two directions.

Hydraulic cylinders are essential components in hydraulic systems and are used in various industrial applications.

Here are some types of hydraulic cylinders:

- Single-acting cylinder

Has only one hydraulic port and can move a load in one direction. Typically used in applications requiring linear motion in one direction.

- Double-acting cylinder

Has two hydraulic ports and can move a load in two directions. Typically used in applications requiring linear motion in two directions.

- Telescopic cylinder

Has multiple piston stages that can be extended and retracted. Typically used in applications requiring long linear motion.

- Welded cylinder

Made by welding its components together. Typically used in applications requiring high strength and durability.

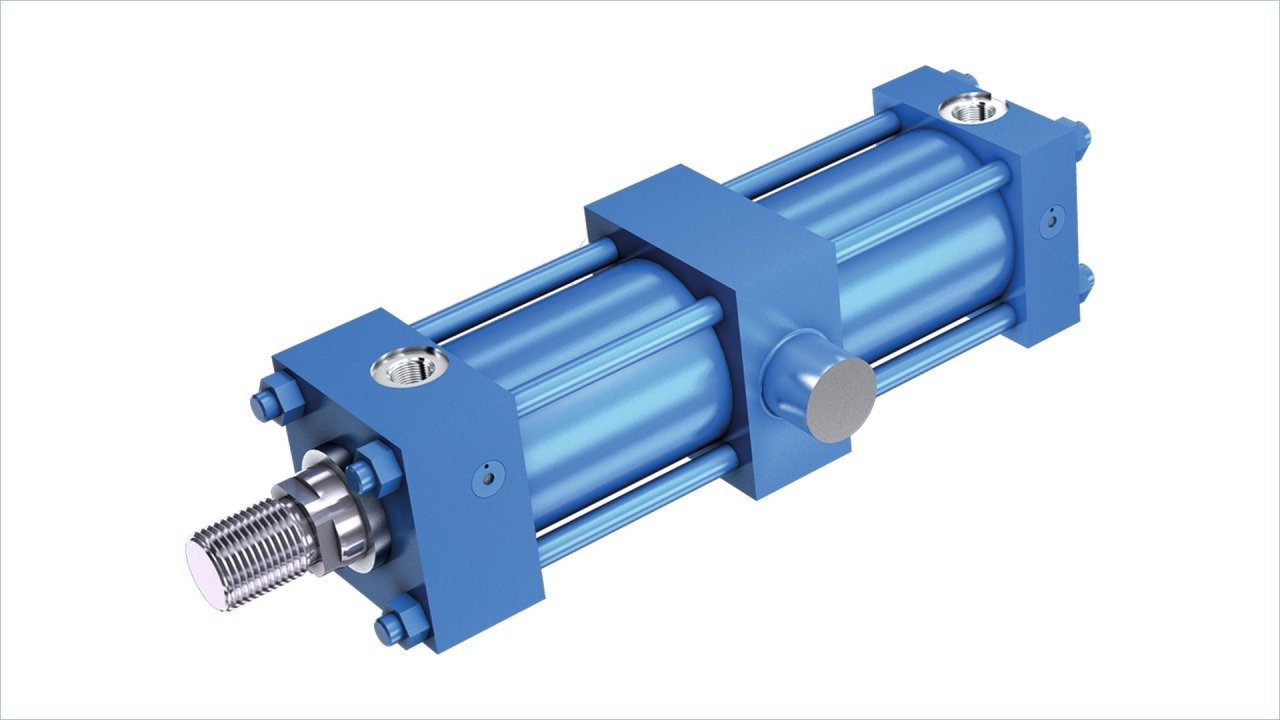

- Tie rod cylinder

Has a tie rod connecting the cylinder head to the cylinder base. Typically used in applications requiring high strength and durability.

- Mill-type cylinder

Designed for applications requiring very high strength and durability, such as in the mining and construction industries.

- Specialty cylinder

Designed for special applications, such as cylinders that can operate in extreme temperatures or corrosive environments.

Each type of hydraulic cylinder has its own advantages and disadvantages, and is selected based on specific application needs.

” We are the official distributor of Rexroth and have spent several decades building trust and offering quality products to be an industry leader in the manufacturing and supply of hydraulic systems, lubrication systems, filtration systems, and fire suppression systems. “